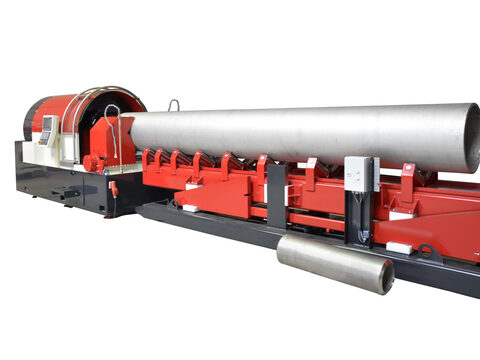

Beaver S Series

- Operates with form tools

- Machining range: 0,25" to 56"

- Wall Thickness: Up to 25mm in one pass

Offshore pipelines have an important role in oil and gas transportation to many areas via large water expenses. Following the international pipeline design codes and standards is crucial in offshore pipelines. It is also important to have high-quality and durable pipelines to contend with the risk of corrosion, high-temperature, earthquakes, and any other threatening seismic activity. The design of the pipeline and choosing the right materials are as important as the construction of the pipeline; where Copier Machinery can play an essential role to meet the requirements.

Pipes used in the offshore industry can vary by diameter and wall thickness, which can consume time and reduce the quality of the pipe preparation process if the correct machinery is not chosen. The automated solution for beveling will maintain the end-quality for each pipe operation and increase efficiency.

Offshore pipeline systems are available in different materials:

Our Beaver S automatic and CNC machines meet the offshore pipeline quality requirements and allow you to better use your manpower and fabrication facility space.

While the machining range of Beaver S automatic series is between 0.5” and 48” (12.7mm – 1230mm), and the maximum wall thickness is 25mm in one pass, the Beaver CNC series can machine tougher pipe materials like stainless steel, duplex, or super duplex and the wall thickness is unlimited.