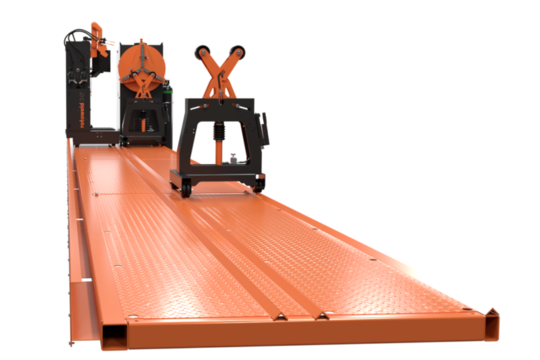

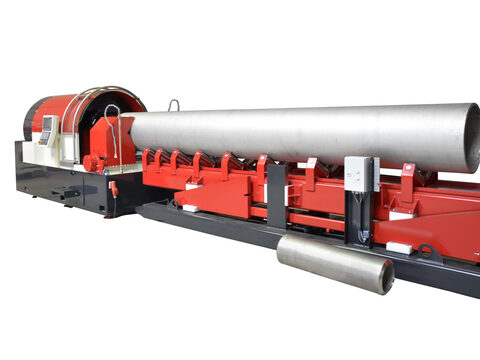

Pipe cutting and beveling in one pass with Beaver CB

The Copier Beaver CB Series is a beveling and cutting machine in one; beveling and cutting are performed in one process flow. This makes the machine not only time-efficient but also space-efficient while minimizing the internal transportation of the pipes. As the machine allows you to do multiple operations there is no need for separate cutting and beveling machines.

The Beaver CB is a CNC-controlled machine that is able to create almost any welding type such as J-prep, V-bevel, tapering, facing, and squaring without changing tools. The machine can bevel pipes with unlimited wall thickness and provides high-quality cuts and bevels continuously. Its user-friendly design and interface allow an operator to function after 2 days of training. The Beaver CB is customizable to meet your specific production requirements. Moreover, the machine can be integrated into an automated production line.

.jpg)

.jpg)