Make the pipe grooving process easier with the Groove Master!

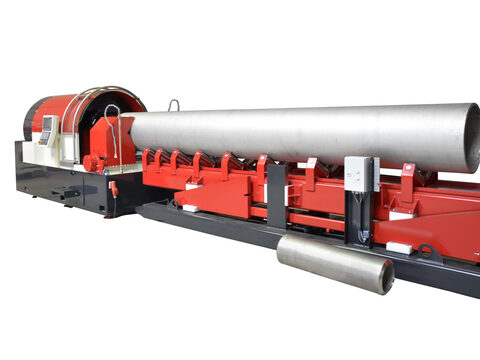

The Groove Master works electro-mechanically and is built robustly and stably. The machine is developed for stationary use; for high production volumes. It enables you to groove pipes with the correct depth; the grooving depth could be adjusted by one-tenth of a millimeter by changing the setting on the machine. There is no need for mechanical adjustments to optimize the grooving depth. The grooving parameters and batch specifications (tube diameter, wall thickness, length, material, and the number of pipes in one batch) can be entered manually and saved for later or can be chosen among the available recipes within the program.

The IoT/Cloud system allows you to reach the production data and track your performance. It simultaneously allows us to access your machine remotely and provide service and support as quickly as possible. The machine is solid and durably constructed for heavy-duty use and accurate grooving of metal pipe ends.

Grooved pipe manufacturers can improve their operators working conditions as the machine produces no flaring, no leakage, and less noise. The machine possesses an easy and quick setup on the screen enabling everyone to operate the machine.

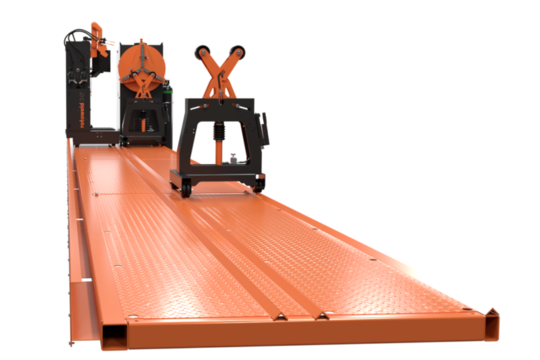

Apart from the stand-alone machine, grooving cells are available where pipe handling is included.

When you need a modified groover machine, our engineering team can help you to have the custom modified pipe roll grooving machine that fits perfectly with your business and production requirements.

.JPG)

.jpg)

.jpg)