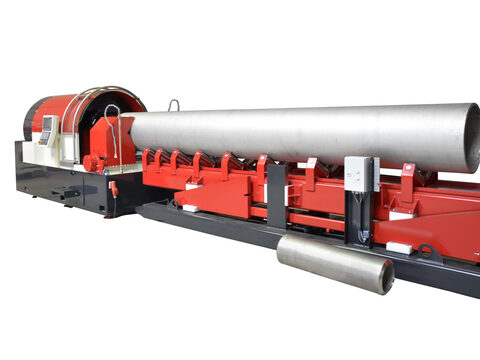

Beaver S Series

- Operates with form tools

- Machining range: 0,25" to 56"

- Wall Thickness: Up to 25mm in one pass

A piping system consists of prefabricated components; these components are called pipe spools. Pipe spools include pipes, flanges, fittings, elbows, tees, etc. Pipe spools connect long pipes with flanges at the ends so they can be attached to another pipe with a matching flange.

Refineries, power plants, oil & gas production facilities, and petrochemical plants require intensive piping as the pipes are used to transport fluid and gas. Pipe spools are therefore suitable for these industries.

Pipe spools are manufactured using raw pipe and pipe fittings. The raw pipes are cut to pre-defined dimensions suitable for the pipe fittings and other components. They are generally manufactured in the fabrication shop by following a series of cutting, beveling, welding, and other processes depending on the design and requirements. Pipe spool fabrication is a critical stage not only for piping but also in an overall industrial construction project. Assembly needs to be done precisely; there is no room for mistakes.

The diameter of the pipe spool (“) is the determinant of the choice of equipment for pipe preparations. The Beaver series for pipe cutting and beveling has a full range for the pipes outside diameter between 0.5” and 56” with manual, automatic, and CNC options. Our machinery is suitable for mass production, reliable for 24/7 fabrication, and ideal for smooth and precise finishing.

Currently, the most common productivity factor in the pipe spool fabrication process is the diameter inches of welded spool per man-hour. To increase the productivity in the fabrication, we offer Rotoweld 3.0 that is a fully automated MIG/MAG pipe spool welding machine that ensures full-penetration 1G girth welds five times faster than manual SMAW or GTAW.

The unique patented technology increases productivity by 400% thanks to its unique algorithm that provides easy adjustment in welding parameters, such as travel speed, wire feed rate, arc voltage, or weaving.